It's

REAL

It's

MAMMOTH

It's BETA

It's

REAL

It's

MAMMOTH

It's BETA

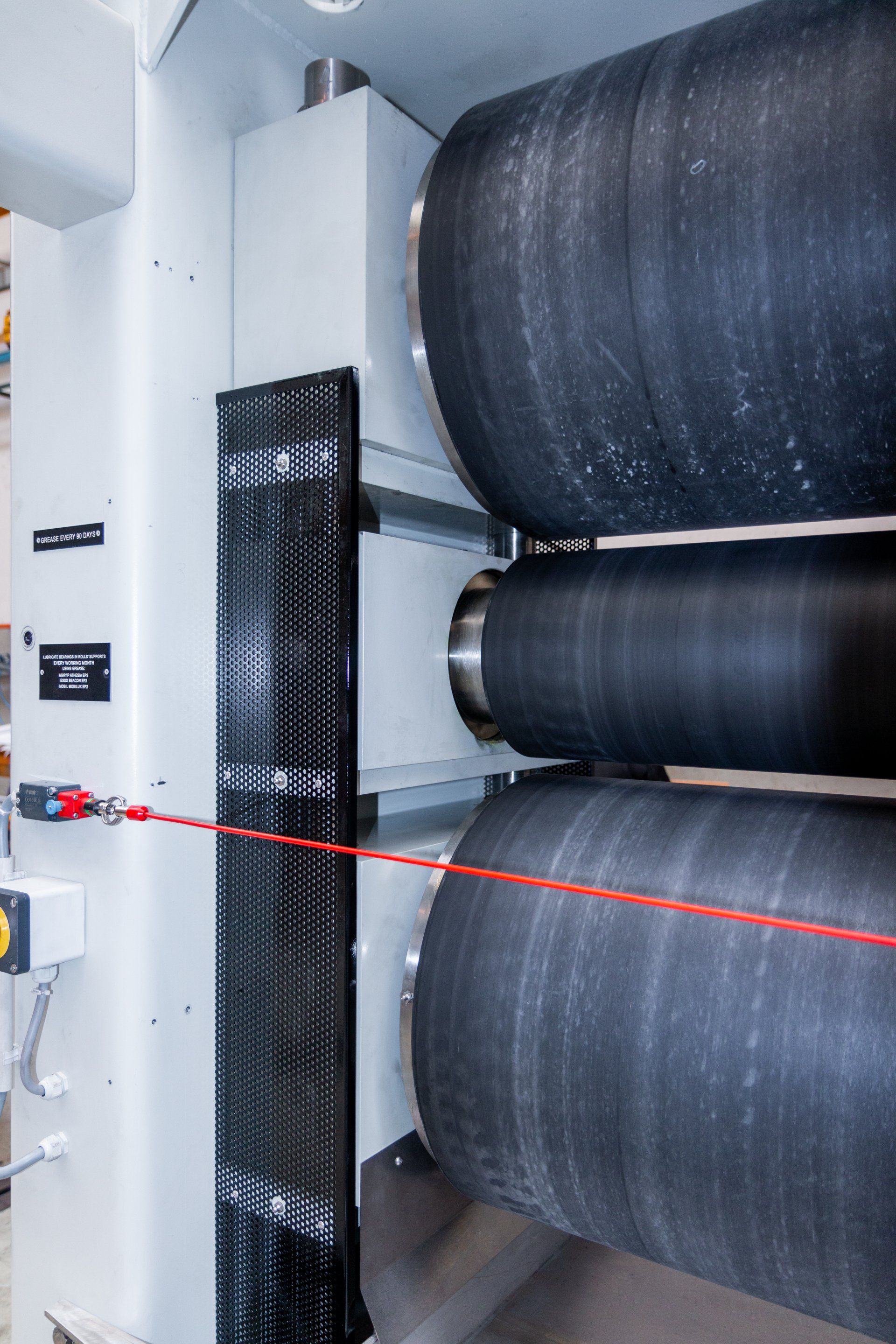

BETA "Mammoth"

Padder

equipressure system

7000mm Beta-Rolls(R)

BETA "Mammoth"

Padder

equipressure system

7000mm Beta-Rolls(R)

Textile, technical textile, and nonwovens

Impregnation / Squeezing

Impregnation / Squeezing

Features

Features

After months of relentless brainstorming, meetings, sketches, 3D designs, and hundreds of FEAs, pushing our experience and know-how to the limits of technical feasibility, and with the objective of producing a machine that could respect the most recent requests from the market (namely, a huge tablewidth), we came up with the most impressive, powerful, precise, and biggest Padder ever.

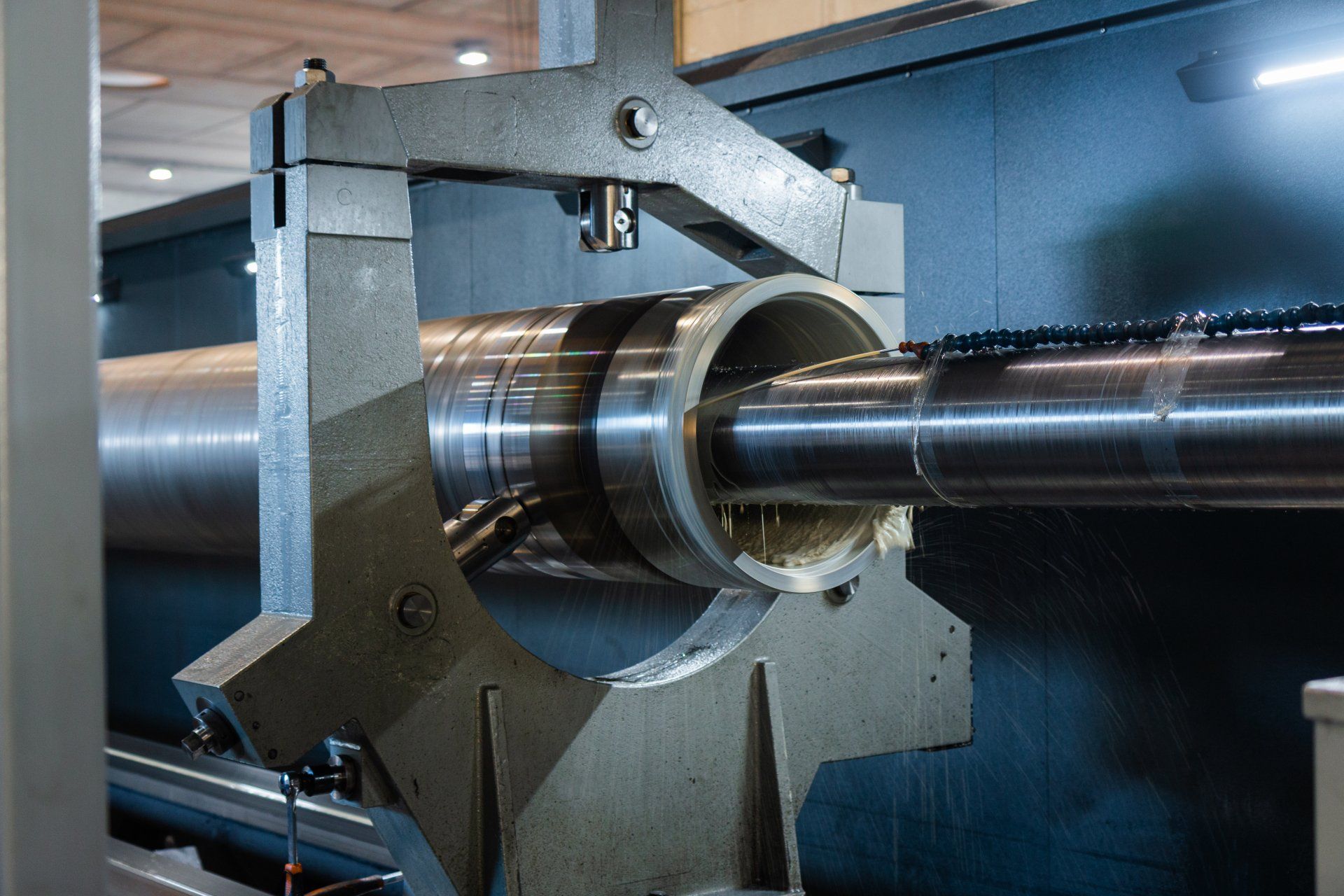

The key difference between Beta and our competitors is the Beta-Roll(R) that guarantees the equipressure of the rolls at any working pressure, giving a uniform squeeze on the whole width of the fabric or web.

The Beta “Mammoth” Padder boasts a tablewidth of 7000mm and is used to impregnate and squeeze fabrics and nonwoven webs of any kind (spunlace, spunbond, airlaid, …).

The impregnation of the web takes place in a stainless-steel trough, where you can apply any sort of dye or chemical (antibacterial, antiviral, antimicrobial, antistatic, waterproof, flame retardant, UV resistant…).

This unique machine is the only Padder on the market that reaches a tablewidth of 6500mm, and, with a very short length of 1800mm, can be easily adopted even in already functioning production lines.

For the BETA Mammoth Padder a new 6500mm Beta-Roll(R) has been designed, with improved internal features optimized for this tablewidth.

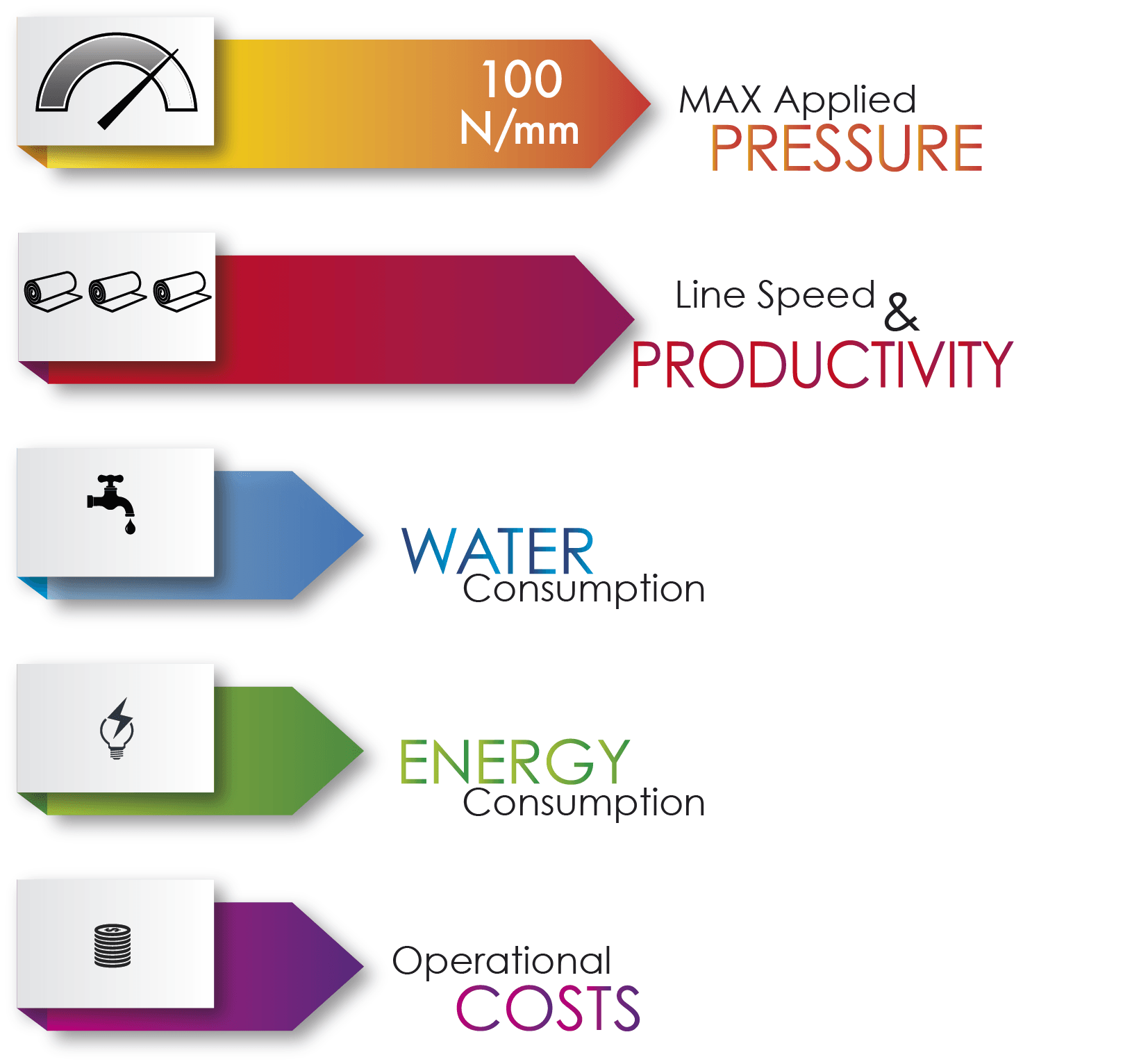

The enhanced pressure system delivers an impressive squeezing power that gives our Customers many key advantages:

- the uniform squeeze guarantees an even distribution of the chemicals that turns into the best quality of your fabric/web. The same amount of chemical is spread on all the surface of the fabric/web and is not jammed along the centerline. This result is unreachable with traditional rolls or even with crown rolls.

- with this giant squeeze you can save an enormous quantity of water and chemicals, be more sustainable toward the environment, and lower your levels of environmental pollution.

- the massive working pressure leaves the minimum quantity of water and chemicals in the web, and this means important energy economies during the drying phase.

The Beta “Mammoth” Padder is shipped completely assembled, and only a few days are required for installation, startup, commissioning, and training.

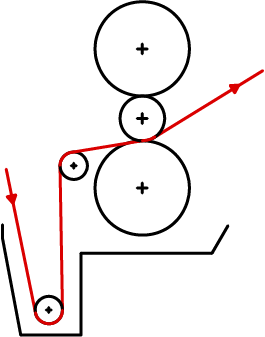

BETA Mammoth Padder Layout

BETA Mammoth Padder Layout